Australian Pulse Bulletin

Lentil: Variety cross-contamination

Key points

- Market options for lentils contaminated with off-type varieties are fewer, at a discount and a low priority.

- Do everything possible to avoid cross contamination of lentil varieties.

- Ideally choose a variety of equivalent seed size and seed coat/kernel colour.

- Alternatively choose varieties that are widely differing in seed size if the seed coat colour differs.

- Paddock selection is critical, as is hygiene to maintain variety purity.

- Delayed sowing helps to eradicate any early germinated self-sown lentils.

- Do not sow dry or early if there is likely to be soil seed bank contamination from the old variety.

- Choose a year with the best seasonal conditions to change varieties.

Lentil receival standards allow no more than 1% contamination of other varieties. It is important for grain marketing that we maintain lentil variety purity and avoid cross contamination of varieties, particularly those with different seed coat colours.

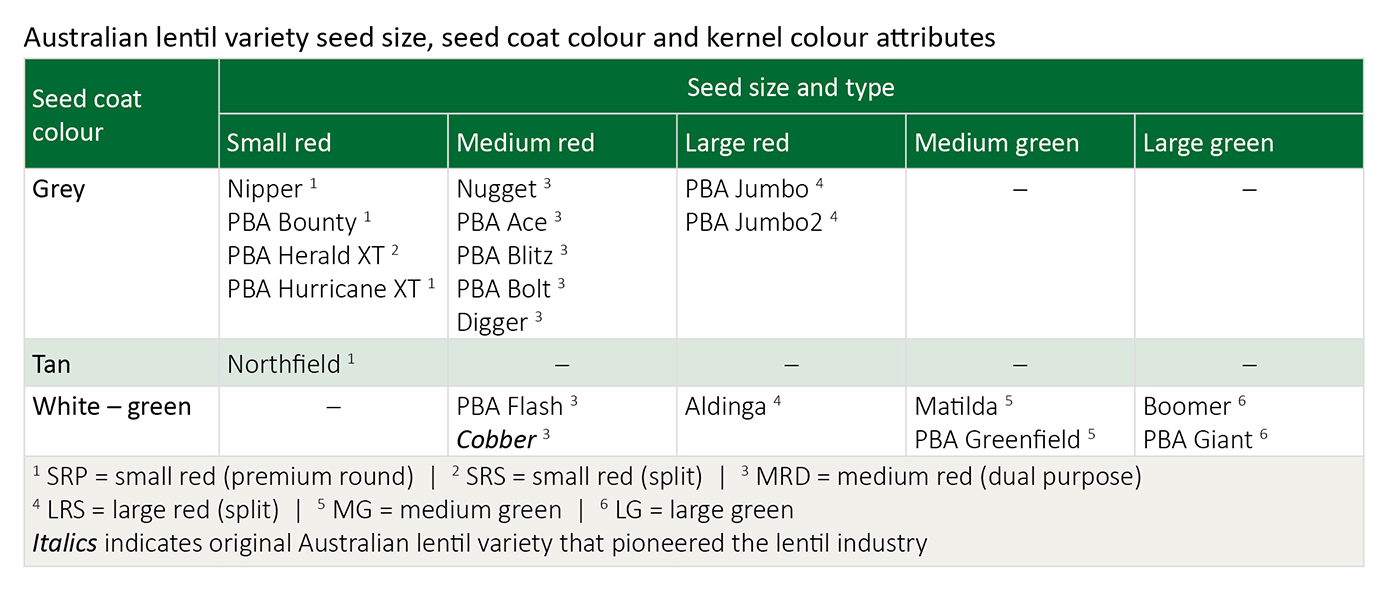

Current lentil varieties differ in both size and seed coat colour. Kernel colour can also differ; red lentils have an orange-red kernel and green lentils have a yellow kernel. Red lentils can also differ in the intensity of redness of the kernels, which could affect the uniformity of the colour of the split product.

Growers must avoid contamination of off-type varieties in lentil grain. Otherwise marketing options are greatly reduced and are often at a significant price discount. Such grain is often only received after all other number one grade grain has been received and marketed.

How contamination occurs

Eventually all red lentil varieties will have a grey seed coat, but in the interim we have different sizes and colours and the need for new varieties to replace the ones currently being grown.

Contamination of lentil varieties comes through:

- Volunteer lentils emerging in the current lentil crop that have arisen from lentils that escape weed control measures in the previous rotational crop and set seed, an inability to control all volunteers before seeding the current lentil crop and hard seeds from previous lentil crops.

- Having an intense lentil rotation with a minimal break between lentil crops. Then changing to a different colour or sized variety.

- Dry seasons. Hard seeded-ness in lentils is more likely to occur in a dry year or a year with a quick finish.

- Contamination of seed during harvesting, handling, storing, cleaning or sowing. This can be minimised by selecting best areas for seed production and following strict hygiene procedures with harvest, storage and handling equipment, particularly with seed crops.

On-farm strategies

To minimise the chance of contamination from off-types:

- Take special care when changing to a variety with a different seed coat colour to avoid off-type variety contamination.

- Give your seed crop area the highest priority for freedom from lentil contamination.

- Choose a paddock that has not grown lentils for three or more years and where a high level of broadleaf weed control has been achieved.

- Ideally select a paddock that last grew lentils in a season that was less likely to have produced hard seeded-ness i.e. a soft finishing season. Drought conditions during grain fill and/or subsequent dry years in the rotation can lead to a higher seedbank of lentil hard seed being present in the soil.

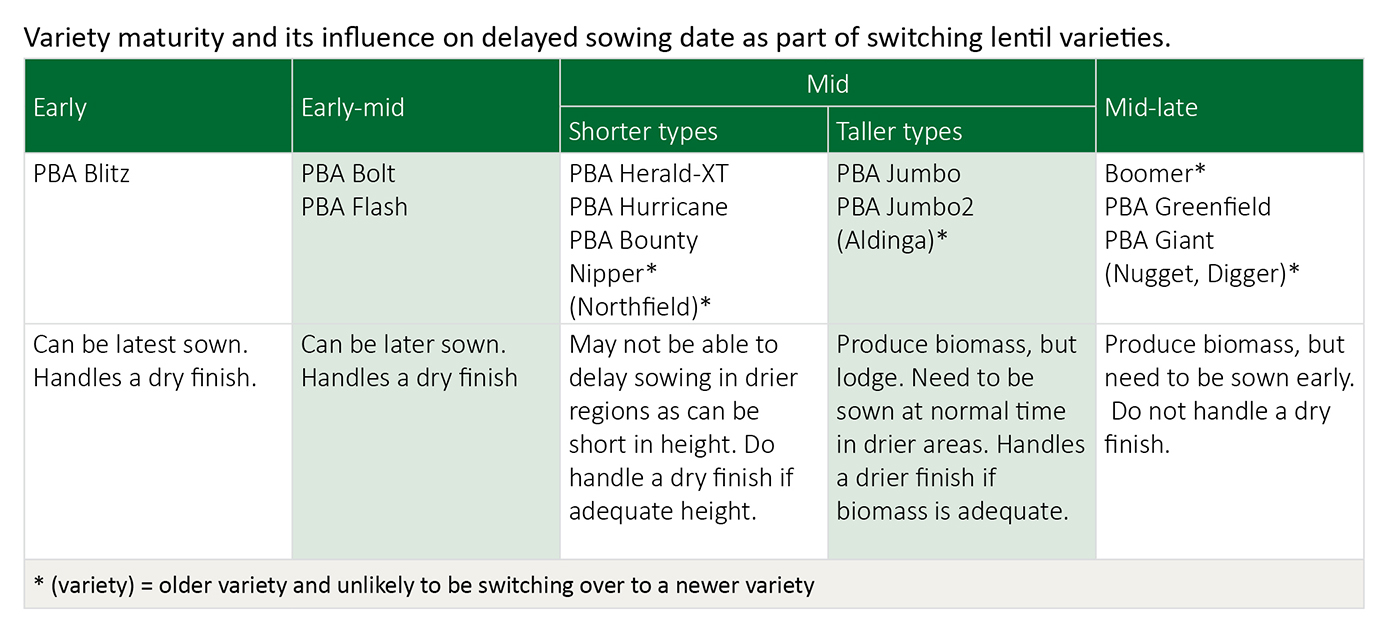

- Dependent upon the prevailing seasonal conditions, delaying of sowing until the later part of the optimal sowing window can be a useful technique. This can often allow for an additional germination of volunteer lentils which can be controlled prior to seeding of a new variety. Delayed sowing is less risky if the variety chosen is early maturing, tall enough and can handle a short or dry season.

- Avoid dry sowing a new variety, especially after a dry summer-autumn when there has not been sufficient opportunity for germination and control of lentil volunteers.

- If appropriate, consider growing a variety of widely different seed size to the old variety (e.g. PBA Jumbo on old Northfield ground). This can help when removing a contaminating lentil variety during grading before sale. The greater the size difference, the better chance of removing the off-type.

Market consequences

If an admixture does occur, the marketing options are significantly reduced and a price discount will apply. Such grain holds a lower priority with marketers as it is more difficult to place, especially in seasons when most lentil production is of number 1 grade and easily exported.

There are some fall-back management options that may help if caught with an admixture. Seed size differences have a considerable impact on the effectiveness of these options.

If you are selling to a processor that splits the lentils for export, then they might be able to more easily handle a variety that is of the same size, but different seed coat colour (e.g. Nipper sown after Northfield). The end-product can still be number 1 grade splits but as a whole grain would fail the number 1 grade standard. Price discounts are still likely though as the admixture can only be destined for sale as splits and not whole product.

Grading is an option if there is a significant difference in seed size. Some processors might reluctantly take the admixed product at a discount if they can machine dress it on a gravity table. If there is a significant difference in seed coat colour then grading may be possible through the use of a colour sorter. Both of these options have costs and losses associated with them and are considered to be a last resort. Admixtures of a similar size and/or similar seed coat colours are near impossible to separate by either gravity grading or colour sorting.

Colour sorting of the split product would be necessary if red lentils are contaminated with green lentils (e.g. Boomer in PBA Flash). This is a very slow, expensive process and creates losses when the yellow splits ('blondes') are removed from the red splits. Few processors have the ability to colour sort.

An admixture of lentil varieties of different sizes would be considered undesirable grain to split since the efficiency and recovery would be reduced and there would be a greater percentage of kibbles. Grading on seed size before-hand might help, but again is inefficient.

Some traders might find a direct export market for the admixed lentils, but at a discounted price. Storage on-farm would be necessary as it often takes time before these markets become available, especially during periods when there is a large supply of number 1 grade lentil available to the trade.

Key contacts

Disclaimer

Information provided in this guide was correct at the time of the date shown below. No responsibility is accepted by Pulse Australia for any commercial outcomes from the use of information contained in this guide.

The information herein has been obtained from sources considered reliable but its accuracy and completeness cannot be guaranteed. No liability or responsibility is accepted for any errors or for any negligence, omissions in the contents, default or lack of care for any loss or damage whatsoever that may arise from actions based on any material contained in this publication.

Readers who act on this information do so at their own risk.

Copyright © 2015 Pulse Australia

All rights reserved. The information provided in the publication may not be reproduced in part or in full, in any form whatsoever, without the prior written consent of Pulse Australia.

Last updated: 20 November 2015