Image 1 – CSIRO field evaluation of herbicide effects on HB1 and other soybean varieties.

Nutgrass control using Sempra in herbicide tolerant soybean varieties

Technical content provided by Rob Walker1, Matthew Moyle2, Natalie Moore3 and Andrew James4

1 Nufarm Regional Development Manager- Coastal & Central, 2 Nufarm Territory Manager- Nth NSW Coastal, 3 Research Agronomist, Northern Cropping Systems, NSW DPI, Grafton, 4 Soybean Breeder, Plant Industries, CSIRO, St Lucia

Take home messages

- The only soybean varieties with tolerance to Halosulfuron-methyl (i.e. Sempra®) are New Bunya HB1A, Mossman HB1A and Kuranda HB1A.

- APVMA Permit number PER88483 for Sempra® (750 g/kg Halosulfuron-methyl) is for the control of nutgrass (Cyperus rotundus) in soybean, effective from 31 March 2020 to 31 March 2023. Note the restraints, critical use comments and withholding periods on the permit.

- Temporary maximum residue limits (TMRL) have been established to allow treated produce to be used domestically for human and animal consumption. Discuss use of Sempra® with marketers of final produce to ensure residues/limits of importing countries are not exceeded.

- Control established weeds with knockdown herbicides or land preparation prior to planting the crop.

- Ensure correct crop stage. For optimal results, apply 65–130 g/ha early post-emergence to the crop (up to 1st trifoliate leaf stage), when the majority of the nutgrass is at the 3–4 leaf stage.

- Coverage is important. Apply in a minimum 80 L water/ha utilising a COARSE spray quality.

- Always apply with adjuvant such as Supercharge® Elite (Paraffin oil 471 g/L) or Banjo® (Methyl esters of canola oil 725 g/L) at 1 L/100 L.

- Only ONE (1) application is permitted per season.

- Read and understand the conditions of the PERMIT and the Sempra® label prior to use.

Considerations

1. How does Halosulfuron-methyl herbicide work

Sulfonylurea (SU) herbicides inhibit the acetolactate synthase (ALS) enzyme in plants. The ALS enzyme, which is responsible for manufacture of branch-chain amino acids, subsequent protein manufacture and plant growth, is blocked at the growing point, resulting in plant death.

Sulfonylurea (SU) herbicides are taken up by the roots, shoots and foliage. Herbicides in this group differ in whether their activity is predominantly through root and shoot uptake, or foliar uptake, or both.

Sempra® (active ingredient Halosulfuron-methyl) is a Group B herbicide that is absorbed through roots, shoots and foliage, with the active ingredient being translocated through the plant to the nutgrass ‘nuts’ (tubers) below the soil surface. Nutgrass exhibits a complicated interconnected network of tubers through underground rhizomes (stems). Sempra® does not translocate through rhizomes to attached tubers, so subsequent germinations may require alternative control measures.

The breeding of soybean varieties tolerant to Halosulfuron-methyl herbicide by the Australian Soybean Breeding Program has enabled Sempra® to be applied as a foliar spray (under APVMA permit PER88483, expires 31 March 2023) early post-emergence (up to the 1st trifoliate leaf stage of the crop) to target nutgrass at the 3–4 leaf stage.

Symptoms of successful weed control are a gradual yellowing of foliage and seed heads followed by desiccation. Initial symptoms may take 7 to 10 days to be noticeable, with full effects occurring 4 to 6 weeks after treatment.

Based on this application timing and utilising Sempra® as a selective, post-emergence herbicide, application to optimise foliar uptake is essential.

In Australia, there is limited data available on the efficacy of Halosulfuron-methyl on weeds other than nutgrass, Navua sedge and Mullumbimby couch. It is, therefore, recommended to discuss with your agronomist complementing Sempra® targeting nutgrass with numerous other herbicides registered for soybean production, some of which are listed below.

*Pre-plant or post sowing pre-emergence:** Bouncer® 960S (S-Metolachlor 960 g/L), Broadsword® (Flumetsulam 800 g/kg), Kyte™ 700WG (Imazethapyr 700 g/kg), Rifle® 440 (Pendimethalin 440 g/L), TriflurX® (Trifluralin 480 g/L) and Tomahawk® (Metribuzin 750 g/kg).

*Post-emergence:** Claw® 350SL (Imazamox 350 g/L present as the ammonium salt), Dictate® 480 (Bentazone 480 g/L present as sodium salt), Exert® 520 (Haloxyfop 520 g/L), Factor® (Butroxydim 250 g/kg), Havoc® (Clethodim 240 g/L), Kyte™ 700WG (Imazethapyr 700 g/kg).

*Refer to labels for specific use patterns.

2. Successful application

Attention to detail with application set-up is crucial to ensure desirable coverage and uptake of Sempra® applied as a selective, post-emergence foliar spray.

For successful results it is important to ensure the following:

- Spray rig is accurately calibrated.

- Apply Sempra® in a minimum of 80 L water/ha utilising a COARSE spray quality.

- Always apply with an adjuvant such as Supercharge® Elite (Paraffin oil 471 g/L) or Banjo® (Methyl esters of canola oil 725 g/L) at 1 L/100 L.

- Do not spray when crop and/or weeds are stressed due to low relative humidity, temperature extremes, waterlogging, or when severe root or foliar diseases are present.

- Do not spray if storms or heavy rain is anticipated within at least 48 hours.

- Experience suggests optimal results from application just prior to light rainfall or irrigation.

- Crop nutrition is managed to avoid nutritional deficiencies and plant stress.

3. Plant back periods

Pesticide residues need to be taken into consideration in determining plant back intervals to subsequent crops and resulting future cropping opportunities.

The crops listed in Table 1 may be planted at specific time intervals following application of approved rates of Sempra® in approved situations. Use the time intervals listed below to determine the required time interval before planting.

Table 1. Extract from the Sempra® label for plant back periods

In the circumstance of a failed HB1 soybean crop where Halosulfuron-methyl has been applied, there are no plant back issues if re-planting with a HB1 variety (tolerant of Halosulfuron-methyl), however, this herbicide must not be re-applied to the re-planted crop. If subsequent weeds germinate, manage with conventional herbicide options registered for use in soybean production, excluding Group B herbicides (for example, Imazethapyr, Imazamox, Flumetsulam).

4. Break down in soil

The primary factor for degradation of all SU herbicides in soil is microbial activity. Maintaining desirable levels of organic matter in cropping soil is crucial as it provides a food source for soil microbes.

Other essential factors include:

- soil moisture – increased breakdown with higher soil moisture,

- soil temperature – increased breakdown with warmer soil temperature,

- soil pH – increased breakdown in acidic (low pH) soils and slower breakdown in alkaline (high pH) soils,

- time.

No one path works in isolation. A combination of the factors above results in effective breakdown of SU herbicide residues.

Always follow the product label with respect to plant back timeframes to subsequent crops and discuss your particular situation with your local agronomist.

5. Tolerance of HB1 soybean varieties to Sempra® (Halosulfuron-methyl)

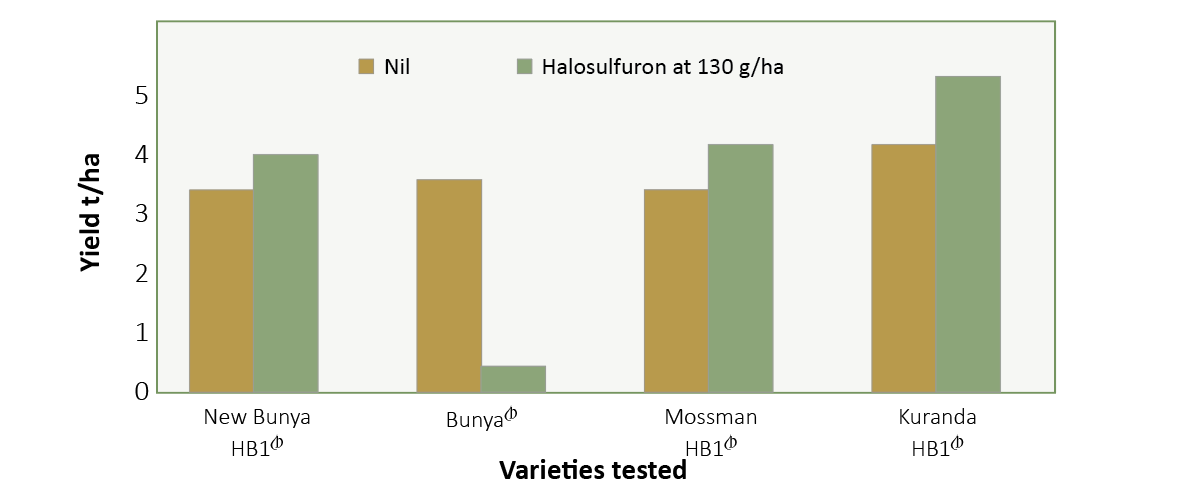

The Australian Soybean Breeding Program has tested three new varieties, New Bunya HB1A, Kuranda HB1A and Mossman HB1A, and an earlier variety (BunyaA), for their tolerance to Halosulfuron-methyl herbicide at a rate of 130 g/ha (Graph 1).

BunyaA was very susceptible while the three HB1 varieties showed a yield improvement in the presence of the Halosulfuron-methyl herbicide treatment.

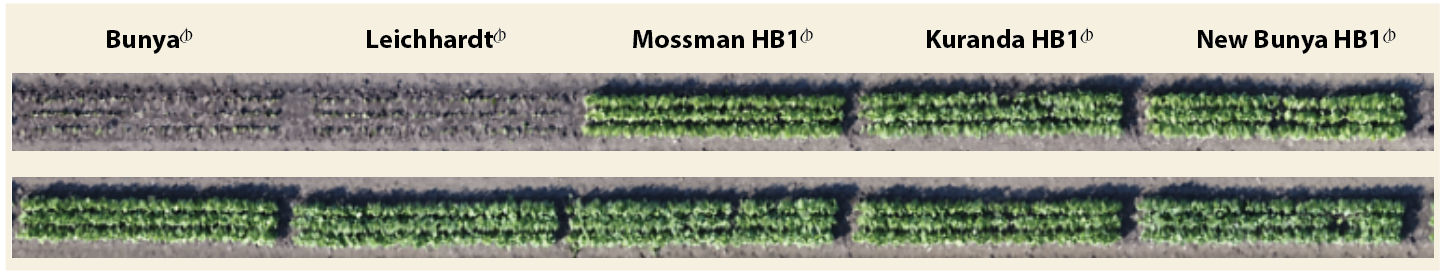

Drone imagery of the trial plot (Image 2) shows the effect of the herbicide application on susceptible and tolerant varieties.

Graph 1: Yield of soybean varieties grown at Gatton in 2018 with and without a treatment of Halosulfuron-methyl at 130 grams per hectare. Within a cultivar, all treatment effects were statistically significant (P <0.05).

Graph 1: Yield of soybean varieties grown at Gatton in 2018 with and without a treatment of Halosulfuron-methyl at 130 grams per hectare. Within a cultivar, all treatment effects were statistically significant (P <0.05).

Image 2 – Drone imagery of trial plots taken 10 days after the treatments were applied, showing the effect of Halosulfuron applied at first fully expanded trifoliolate leaf stage (top), compared to the nil herbicide treatment (lower). Mossman HB1A, New Bunya HB1A and Kuranda HB1A have 1-gene tolerance to Halosulfuron-methyl herbicides while BunyaA and LeichhartdA have no tolerance of these herbicides.

6. Characteristics of the HB1 varieties

New Bunya HB1A

Regional adaptation – New Bunya HB1A is expected to have similar adaption as its parent variety BunyaA. It is well-adapted to irrigated cropping across inland southern Queensland and to northern NSW.

It is adapted to planting from late November though to mid-January. It may also be grown in the Burdekin region of northern Queensland as a winter crop with a May–June planting date.

Market suitability – New Bunya HB1A should be suitable for crushing, full fat processing, and a wide range of human consumption markets. It is anticipated that it will be strongly sought after by tofu makers.

Breeding – New Bunya HB1A is largely derived from its parent variety BunyaA but with several resistance genes derived by backcrossing.

Kuranda HB1A

Regional adaptation – Kuranda HB1A appears to be well adapted to cropping in coastal environments from Nambour north to the wet tropics of Queensland.

In the southern end of the cropping range it is best adapted to planting dates from late December though to early February as at earlier planting dates it may become excessively vegetatively vigorous.

In central Queensland and more northern regions, Kuranda HB1A may be sown from late November through to early February.

In regions of Queensland with warm winter temperatures (average minimum monthly temperatures >15°C) Kuranda HB1A may also be sown in April though to early July.

Market suitability – Grain of Kuranda HB1A appears to be well received in many market segments including crushing, full fat processing and for human consumption such as milk and tofu.

Breeding – Kuranda HB1A has complex breeding. The variety is largely derived from its parent line M103-22 with several resistance genes backcrossed in. M103-22 is a selection from a cross between the Fraser and MoonbiA varieties. Kuranda HB1A is longer crop duration and more broadly adapted than either parent.

Mossman HB1A

Regional adaptation – Mossman HB1A is a green manure option in many Queensland cropping environments due to its long duration and high biomass production.

It may be considered as a grain option in the Burdekin and Atherton Tablelands regions of Queensland.

Market suitability – It is anticipated that grain of Mossman HB1A will be accepted into most crushing, stockfeed and human consumption markets.

Breeding – Mossman HB1A is closely related to its parent variety Leichhardt but with the additional inclusion of a light hilum and some resistance genes derived by backcrossing.

More information

- APVMA PERMIT PER88483

- Nufarm product information and contact details

- Soy Australia factsheets for new HB1 varieties

- NSW DPI Summer Crop Production Guide – Soybean

- GRDC Soybean Northern Region Grow Notes

Acknowledgements

This factsheet is an initiative of the NSW node of the Coastal and Hinterland Grower Solutions project (QDAF, NSW DPI & GRDC co-investment, project number DAQ00204).

The authors gratefully acknowledge the support of Nufarm in preparing this factsheet and advice from Gordon Cumming, GRDC.

Read Pulse Check blog articles | Pulse Check Coastal facebook | Subscribe to the monthly newsletter